Non-Mechanical Vapor Recovery

As a more reliable solution for vapor recovery, COMM developed and patented the EVRU™ technology that uses non-mechanical venturi jet ejectors to compress natural gas. The EVRU™ recovers vent or flare gas using a high-pressure motive gas to entrain hydrocarbons from low-pressure systems such as crude oil storage tanks. The combined discharge gas stream exits at an intermediate pressure and can be injected into the suction of a compressor or into the process system (e.g., fuel gas, low pressure separator).

The EVRU™ is a closed loop system designed to boost and recover natural gas as a usable and profitable product. as an added benefit, it reduces the emissions of methane and volatile organic compounds (VOCS) that are contained in natural gas. The EVRU™ replaces traditional mechanical vapor recovery units and requires virtually no maintenance with no moving parts.

USEPA Performance Test Results (click here to go to EPA’s web site)

Sample pictures of EVRU™ systems:

Tank Vapor Recovery

Crude oil holding tanks can produce large amounts of gas vapor, which when vented or flared release harsh compounds into the atmosphere. Numerous oil producers are starting to realize the advantages of installing tank vapor recovery units, because of their ability to capture harmful vapors, convert them back to liquid state, and either re-insert them back into the crude oil holding tank, or use them as fuel for other applications.

The benefits of installing a vapor recovery unit on a crude oil storage tank can be realized almost immediately upon installation. Capable of capturing up to 99% of the expelled vapor, tank vapor recovery units significantly reduce both the level of vapor wasted, and the emission of harmful, volatile organic compounds into the atmosphere.

EVRU™ FAQ

What is the throughput on our EVRU™?

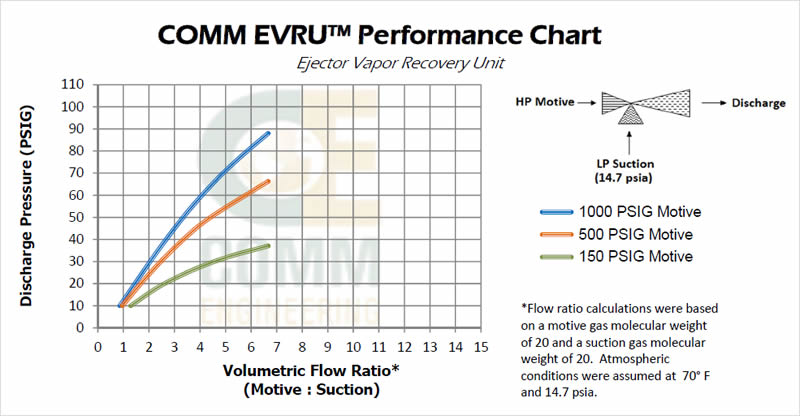

You can use the EVRU™ performance curve (see above) to get an estimate of the required motive gas flow rate for a given motive gas pressure, discharge pressure, and suction flow rate. (For example, if you wanted to use 500 psig motive gas to boost suction gas from 0 to 40 psig, it would take a 5:1 flow ratio…50 MSCFD of motive gas to pick up 10 MSCFD of suction gas.)

Our smallest units are picking up 10 mscfd of suction gas while our largest unit is picking up 2,800 mscfd of suction gas.

What is the pressure differential for the EVRU™? (motive/suction)

Please see abovw EVRU™ performance curve. The pressure differential varies depending on the facility operating conditions and EVRU™ design conditions.

Does BTU matter in sizing EVRU™ capabilities?

No. Pressure and Molecular Weight are critical factors.